Wishbone Center

SPE began its operations in the industry in 2017. Since then, the company has continued its journey with confidence, combining experience and technology to deliver high-tech products.

In addition to stamped control arms, SPE is a leading manufacturer in its sector for a wide range of product groups, including ball joints, control arms with ball joints, tie rods, tie rod assemblies, tie rod ends, control arms without ball joints, control arm bushings, rubber group components, stabilizer links and bushings, repair kits, sway bar links (Z-links), Z-link kits, and forged aluminum and steel control arms with ball joints.

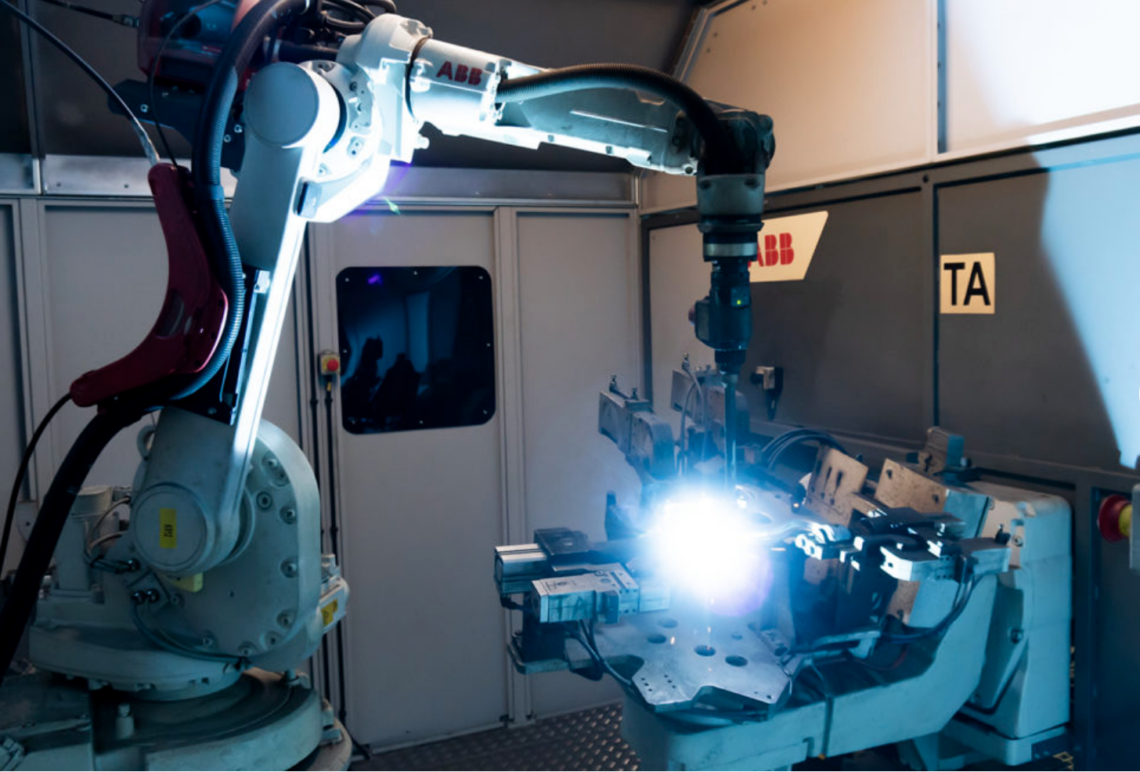

Recognized by its customers as one of the most reliable companies in the industry, SPE is the largest manufacturer in the European aftermarket for suspension and steering parts for passenger and light commercial vehicles. Among these, stamped control arms—found in nearly all modern vehicles—hold significant importance for SPE. In its Stamped Control Arm Facility, all welding operations are carried out entirely by automated robots. Technology and automation are fundamental components of stamped control arm production, and in line with this, SPE has increased its investments in this facility in recent years.

SPE’s Achievements and Vision for the Future

In 2018, SPE implemented a global production facility structure—widely regarded as the most critical strategy for today’s manufacturing industry and the foundation of sustainable growth.

Since 2018, within a 5,000 m² enclosed area of its factory, SPE has been carrying out all stamped control arm production processes—from sheet metal to final product—using modern production lines.

With extensive industry experience, a quality-focused approach, and continuous investments in specialized manufacturing processes, SPE strengthens its leadership in stamped control arm production. Committed to being a solution partner to its customers, SPE delivers high-quality products through five robotic welding lines and servo-controlled bushing and ball joint press systems, fulfilling its on-time delivery commitments with reliability.

SPE operates with full awareness that the products it manufactures play a primary role in ensuring the safety of end users. With this responsibility in mind, the company continuously improves its production processes, aiming to achieve the highest quality standards.

Accordingly, SPE continues its operations with a strong emphasis on the importance of welding processes in stamped control arm production. With the commissioning of CMT Integrated Welding Robots in 2018, SPE once again proved its distinction from competitors, maintaining production that meets OEM quality standards.

Through servo-controlled bushing and ball joint pressing lines, SPE ensures the standardization of its production processes, while its lean manufacturing approach enables customer-specific services through single-line assembly and packaging stations.